Scientific Warehouse Management for Car Wash Tools

28/03/2025 | Admin

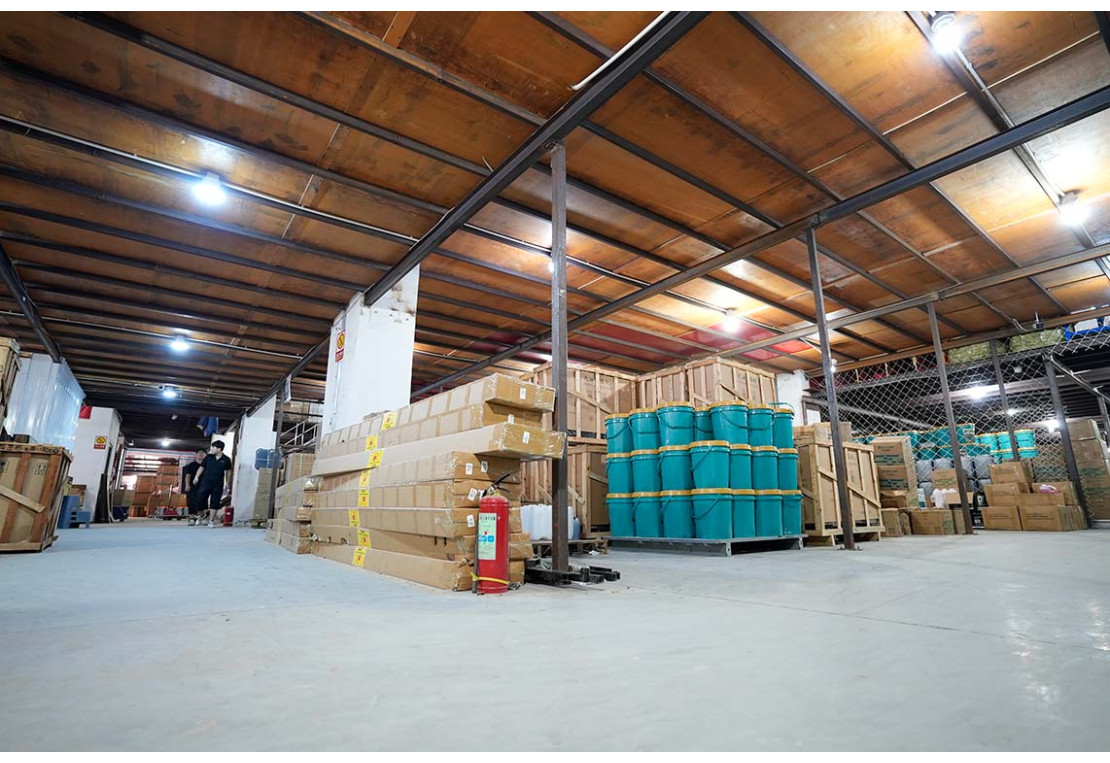

AbstractEfficient warehouse management is essential for optimizing inventory control, reducing costs, and improving operational efficiency in the car wash industry. This article explores key strategies for scientifically managing car wash tools, including classification, storage methods, and digital tracking solutions.

IntroductionCar wash businesses rely on various tools, such as brushes, vacuum cleaners, and pressure washers, to ensure high-quality service. Proper warehouse management ensures these tools are readily available, well-maintained, and systematically organized to reduce downtime and operational inefficiencies.

Key Strategies for Scientific Warehouse Management

Classification and CategorizationOrganizing tools based on their type, usage frequency, and size helps streamline storage and retrieval processes. Common categories include cleaning tools, vacuum accessories, and water-based equipment.

Optimal Storage Methods

Vertical shelving: Maximizes space and provides easy access to frequently used items.

Labeled bins: Helps in quick identification and retrieval.

Temperature and humidity control: Prevents deterioration of sensitive equipment.

Digital Inventory TrackingImplementing RFID or barcode scanning ensures real-time tracking of inventory levels, reducing the risk of stock shortages or overstocking.

Regular Maintenance and InspectionScheduled checks prevent unexpected equipment failures and prolong the lifespan of tools.

First-In-First-Out (FIFO) StrategyEnsuring older tools are used before newer ones minimizes waste and maintains efficiency.

ConclusionA well-organized warehouse enhances efficiency, reduces costs, and ensures a smooth workflow in car wash operations. By integrating scientific management techniques, businesses can optimize their storage systems and improve service quality.